- 1 800 567 4223

- Contact us

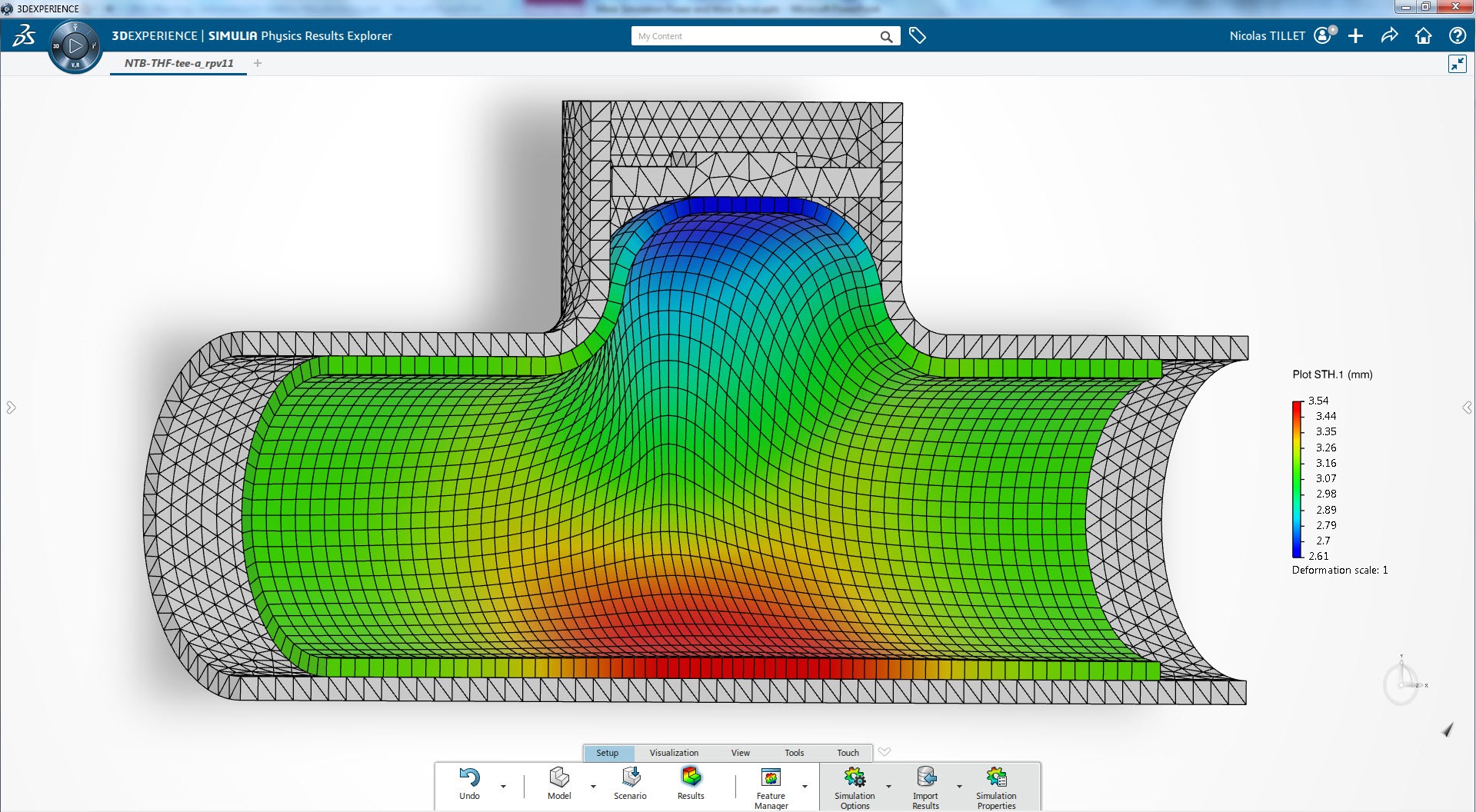

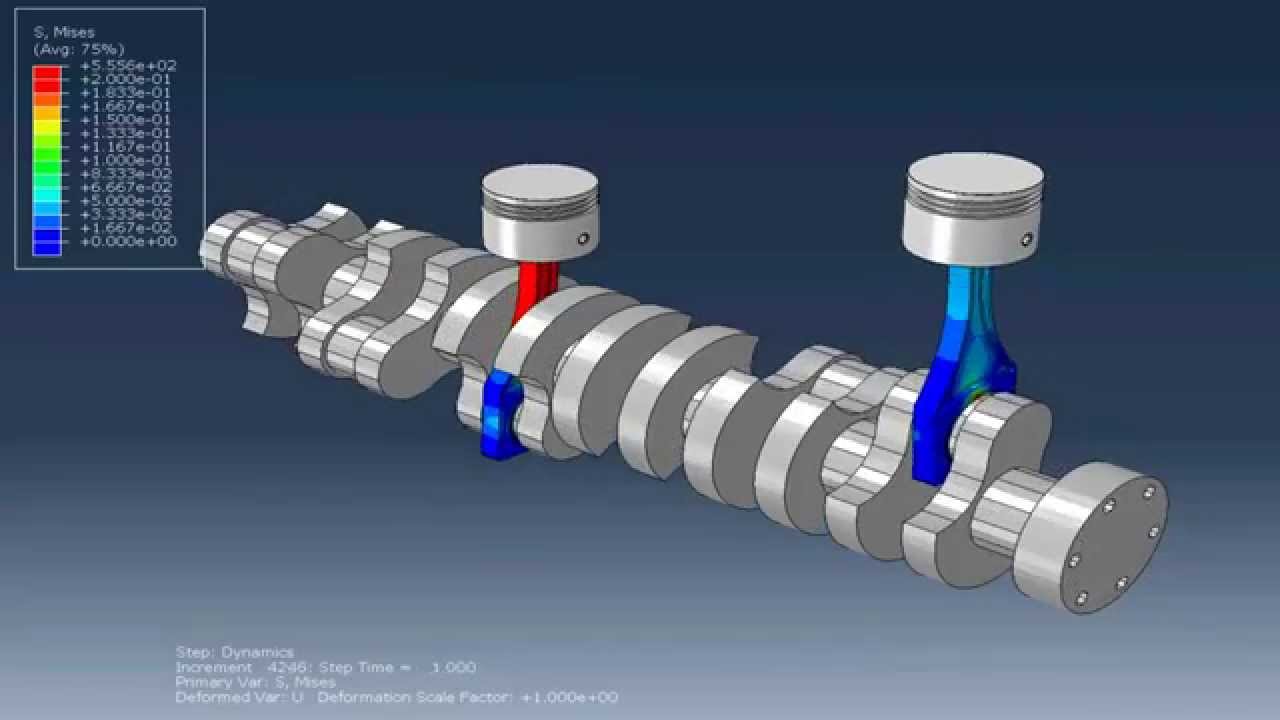

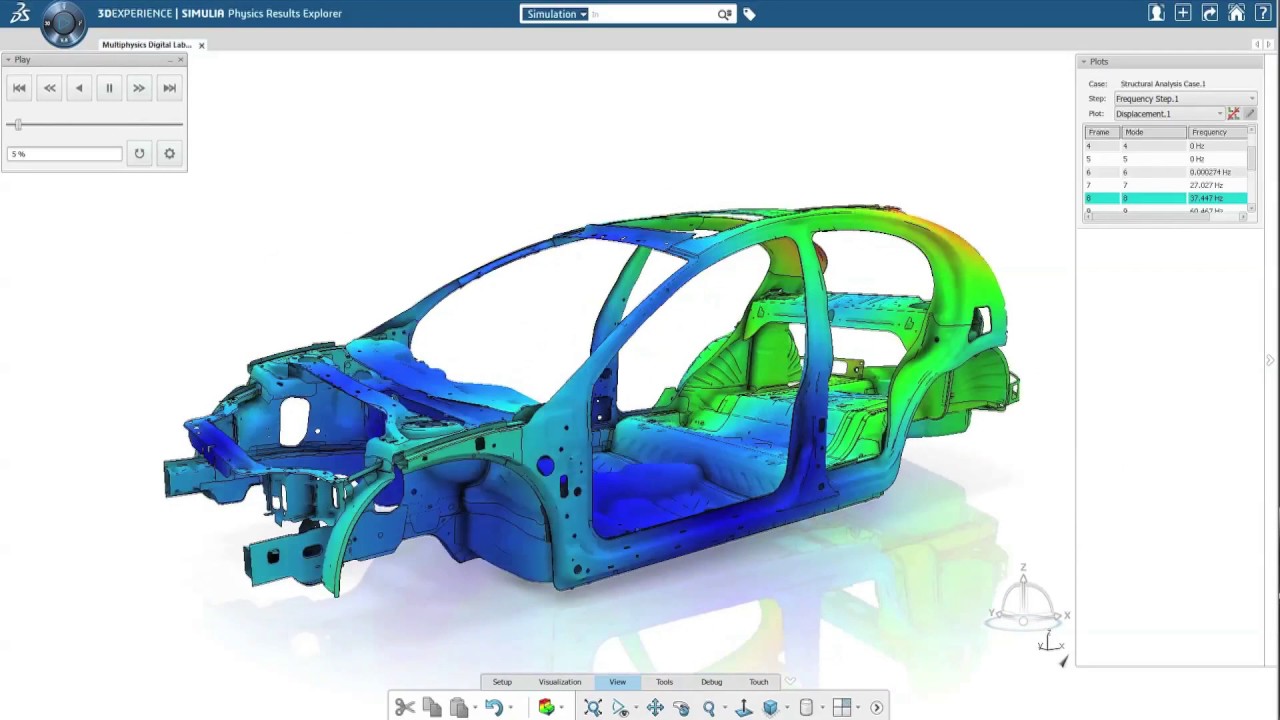

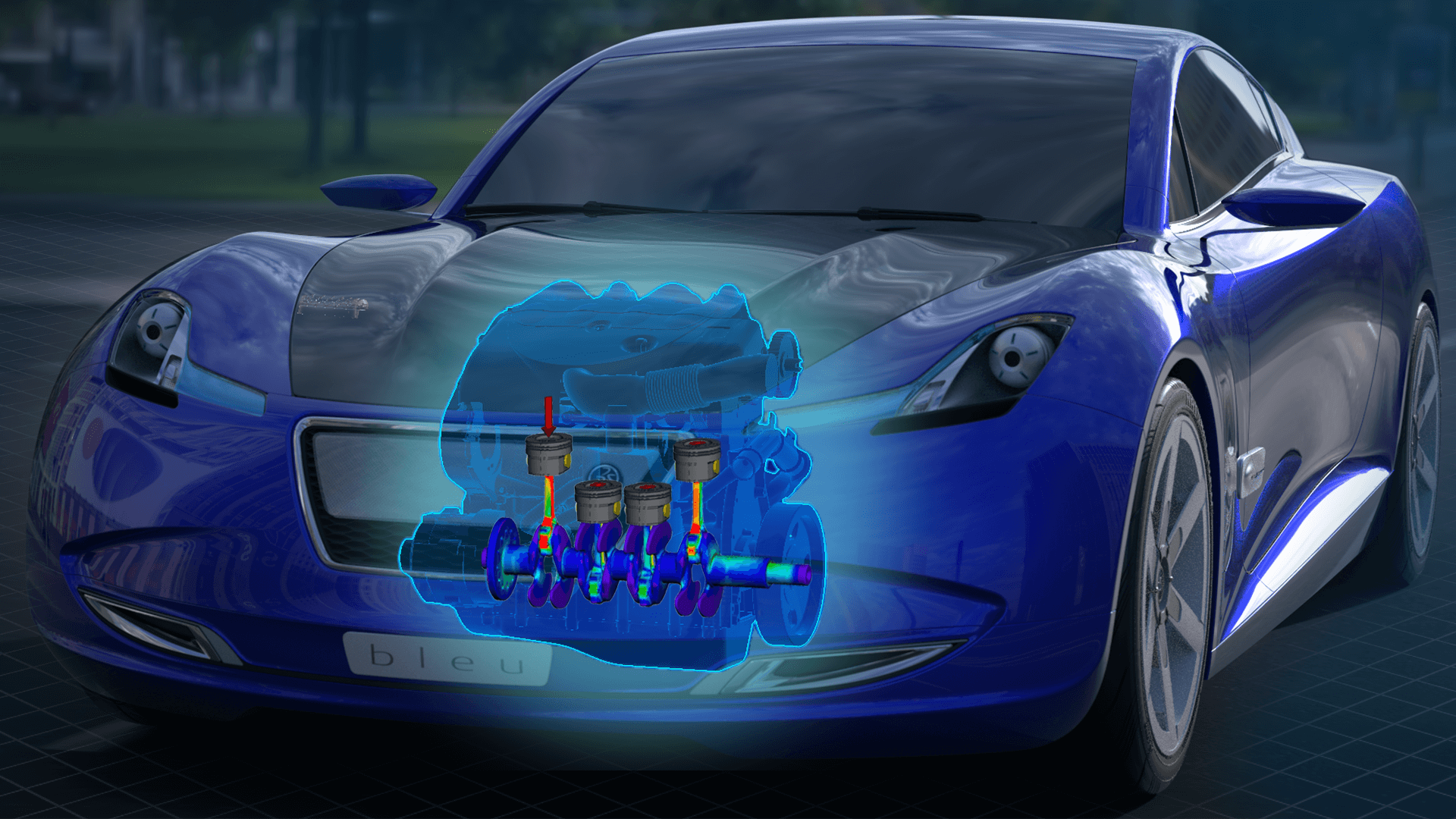

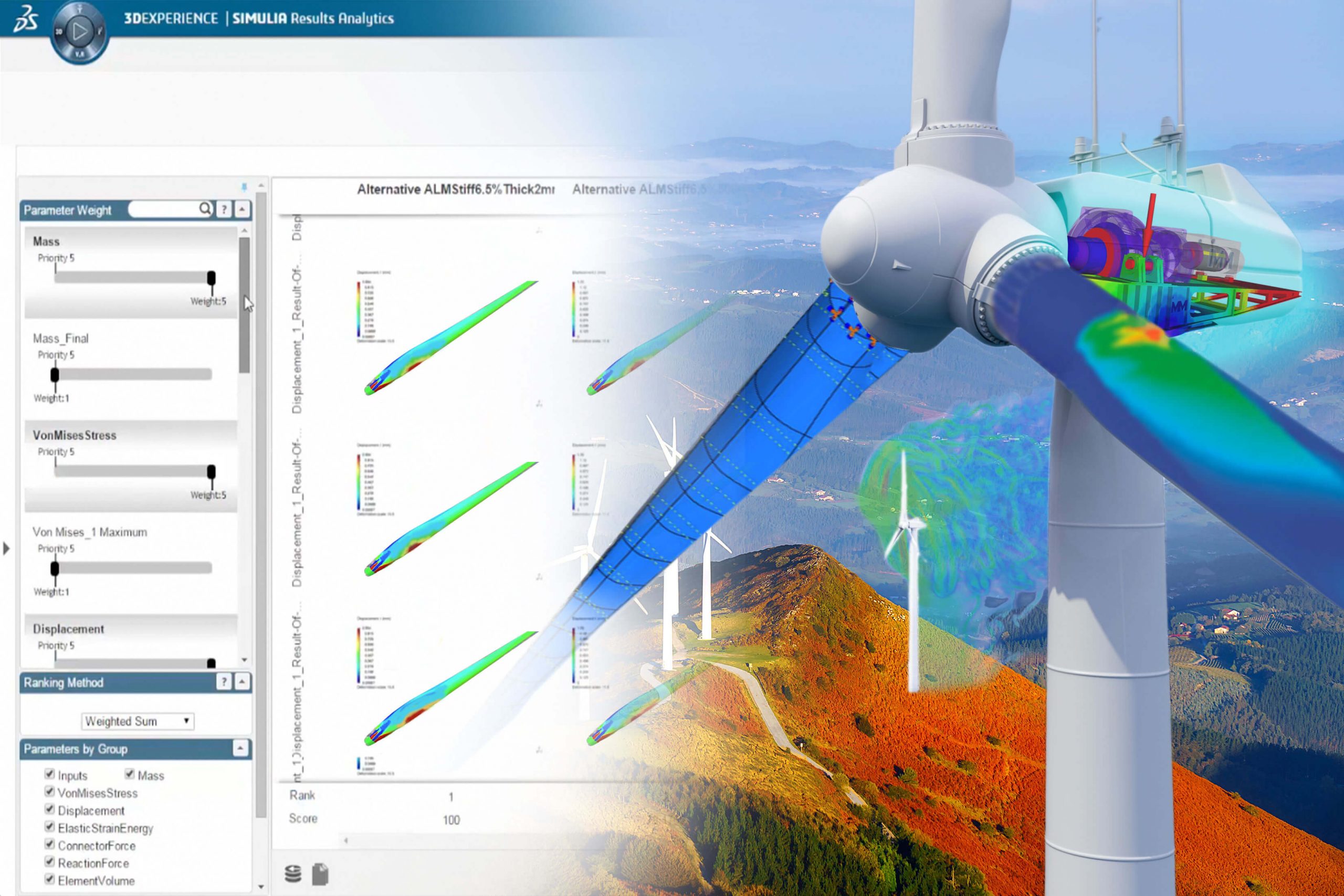

ABAQUS(Simulia) makes virtual testing a standard business practice that improves product performance, reduces physical prototypes, and drives innovation.

Finite Element Analysis (FEA) for Mechanical and Civil Engineering

Finite Element Analysis (FEA) and other structural mechanics solutions simulate how products and assemblies behave under real-world loading and temperature conditions.

Will my design perform as expected, and how can that performance be improved?

Will it break during service or due to misuse? How will it break?

Will it leak?

How long will my product last?

How can I make it last even longer?

The new knowledge generated by answering these questions with Finite Element Analysis (FEA) reduces costs, eliminates errors, and shortens design cycles.

Unlike typical prototype testing, virtual prototypes can tell you much more than just pass/fail. It can tell you why a part will fail and can help you understand whether your improvements will prevent it from falling, and unlike physical testing, mechanical simulation is available 24/7/365.

SIMULIA Structural Analysis Technologies

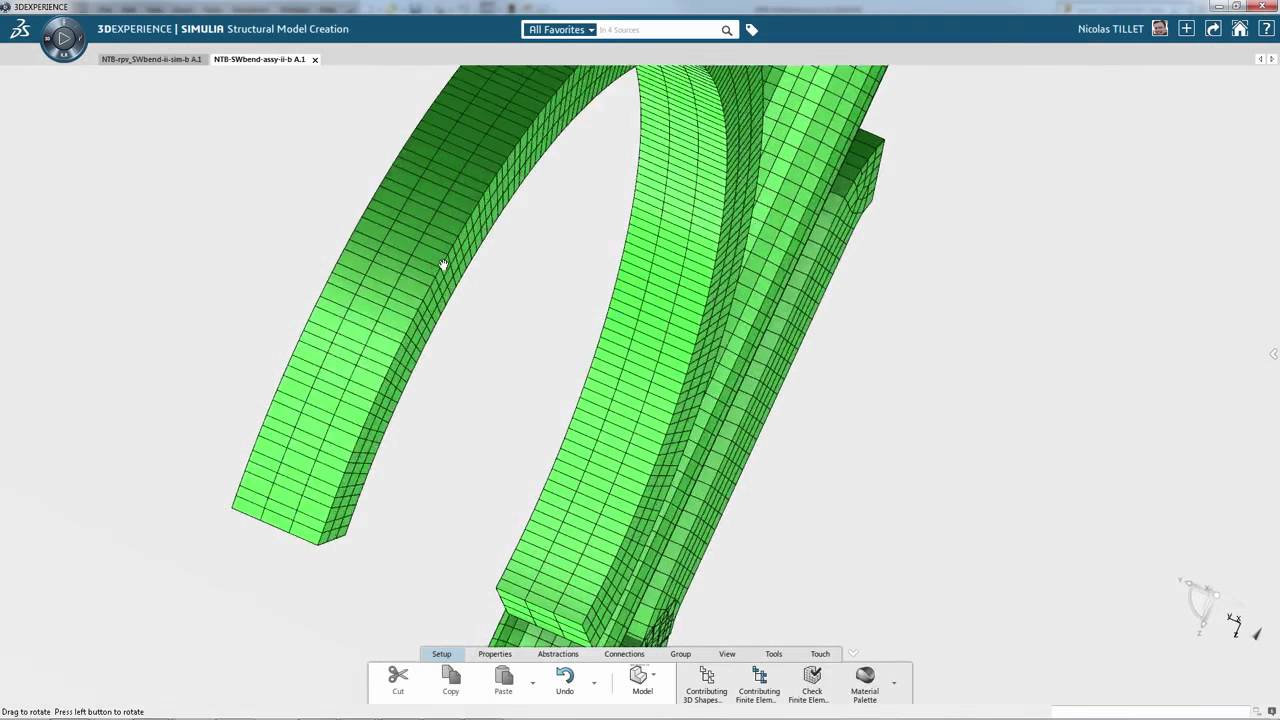

The SIMULIA portfolio in the Structures domain includes Abaqus, fe-safe, and Tosca Structure technologies. Abaqus is a market and technology leader in linear and nonlinear finite element analysis. Both implicit and explicit solution techniques are available and are complementary. Fe-safe technology provides modern algorithms for durability and fatigue life cycle predictions, and Tosca Structure technology provides the ability to optimize the 3D shape and topology of your part to reduce weight and improve strength and stiffness. These technologies are well-known for their power, flexibility, feature set, and performance on modern HPC computer architectures including GPUs and Cloud.

SIMULIA Structural Analysis software products:

Structures on the 3DEXPERIENCE platform

3DEXPERIENCE Works Structures

Abaqus

Simulation for Designers

fe-safe

Tosca

Isight & the SIMULIA Execution Engine

Electromagnetic simulation software enables engineers to investigate the electromagnetic properties of components or whole systems efficiently.

Electromagnetic Simulation Software – Simulation and Analysis of Electromagnetic Fields

EM Simulation can be applied throughout the entire design process, from the inception of an idea to the synthesis of components to meet specifications, to analyzing the electromagnetic performance under operational conditions.

Our software for electromagnetic field simulation covers the whole frequency spectrum, from static to optical frequencies, for devices such as antennas, rf-components, electrical machines, medical devices, and electronics.

Virtual Prototypes are Transforming the Design Cycle

EM Simulation software is a game-changer when it comes to reducing the time and cost of bringing a product to market, not just in the high-tech industries of electronics and communication, but also in aerospace, defense, transportation, and life sciences. Analysis with EM software ranges from individual components such as antennas, sensors, and chips up to entire devices, including aircraft, smartphones, and MRI.

Co-design within the SIMULIA product portfolio integrates EM Simulation into industry processes, accelerating the process of evaluating the performance, reliability, and safety of materials and products before committing to physical prototypes. Multiphysics design flows on the 3DEXPERIENCE platform drive the development process from the earliest stages.

Electromagnetic applications:

Antennas

Microwave Filters and Components Simulation

Bioelectromagnetics (BioEM)

Electromagnetic Compatibility

EDA/Electronics

Particle Dynamics

Low Frequency (LF)

Optical Device Simulation, Plasmonics, and Nanophotonics

SIMULIA Electromagnetic Simulation products:

SIMULIA develops simulation technology that can be used to calculate electromagnetic fields in a wide range of application areas.

Electromagnetics on the 3DEXPERIENCE platform

3DEXPERIENCE Works Electromagnetics

CST Studio Suite

Antenna Magus

Opera

Fest3D

IdEM

Spark3D

Computational Fluid Dynamics (CFD) allows users to engineer products and tackle problems in aerodynamics, noise, lubrication, and plastic injection molding.

Simulations to Improve Real-World Performance

SIMULIA’s Computational Fluid Dynamics (CFD) simulation allows engineers to design products with accurate real-world performance predictions and fast turnaround speeds. SIMULIA’s Fluids technologies allow users to solve a vast array of challenges including eVTOL flight and community noise testing, optimizing race car aerodynamics designs for best performance, certifying automotive designs for WLTP fuel efficiency regulations, or testing the newest airplane models for in-flight safety.

SIMULIA Fluids Simulation is driven by three complimentary technologies that provide powerful, scalable fluids simulation to address a broad range of real-world applications. PowerFLOW and XFlow offer world class Lattice Boltzmann (LBM) for high-fidelity simulations that accurately predict real-world performance. Fluid Dynamics Engineer enables multi-scale multi-physical vision by embedding CFD into design, simulation, optimization, data management, and business intelligence applications within the 3DEXPERIENCE platform. And finally, a dedicated Plastics Injection Molding application allows validation and optimization of plastic part and mold tooling designs earlier in your product development process.

SIMULIA Fluid & CFD Simulation software solutions:

Fluid Simulation on 3DEXPERIENCE platform

3DEXPERIENCE Works Fluid Dynamics

PowerFLOW

XFlow

SIMULIA Cloud

Multibody Dynamics (MBD) simulation software allows engineers to study and investigate the kinematic and dynamic motion of mechanical and mechatronic systems.

Advanced Mechanical Motion Simulation and Analysis Solution

Multibody dynamics is the science of studying the motion of complex mechanical systems under the application of mechanical forces.

Multibody Dynamics (MBD) simulation software enables engineers to observe the kinematic and dynamic motion of mechanical and mechatronic systems, enabling them to generate 3D models to predict and visualize motion, coupling forces, and stresses.

Study Systems from Beginning to End

Multibody dynamics is used throughout the design cycle from initial concept to final detailed design. With multibody dynamics simulation, engineers can:

make informed decisions for quick design changes and study sub- and complete systems

reduce the number of prototypes

avoid costly last-minute changes

speed up time to market

Thanks to its high-end technology, the SIMULIA multibody dynamics product line (which inherits Simpack technology) powers all the SIMULIA applications and is available on the 3DEXPERIENCE platform.

Simulia Motion and Multibody Dynamics Simulation products:

Motion Simulation on the 3DEXPERIENCE platform

3DEXPERIENCE Works Motion Creator

Simpack

Multibody Dynamics Simulation applications:

Create robust simulation flows with process automation, design exploration, and automatic optimization. Automation technology establishes simulation process flows to reduce errors and increase efficiency, as well as methods that automatically explore the design space to find optimal solutions.

Isight & The Simulia Execution Engine – Process Automation and Design Exploration

In today’s complex product development and manufacturing environment, designers and engineers use a wide range of software tools to design and simulate their products. Often, chained simulation process flows are required in which the parameters and results from one software package are needed as inputs to another package, and the manual process of entering this data can reduce efficiency, slow product development, and lead to errors in modeling and simulation assumptions.

Isight and the SIMULIA Execution Engine (formerly Fiper) are used to combine multiple cross-disciplinary models and applications together in a simulation process flow, automate their execution across distributed compute resources, explore the resulting design space, and identify the optimal design parameters subject to required constraints.

Key benefits:

Drastically reduce design cycle time through integrating workflow processes in an automated environment

Deliver more reliable, better-quality products through accelerated evaluation of design alternatives

Lower hardware investments through effective use of legacy systems and more efficient job distribution

Eliminate the bottlenecks of ineffective communication by enabling secure design collaboration among partners

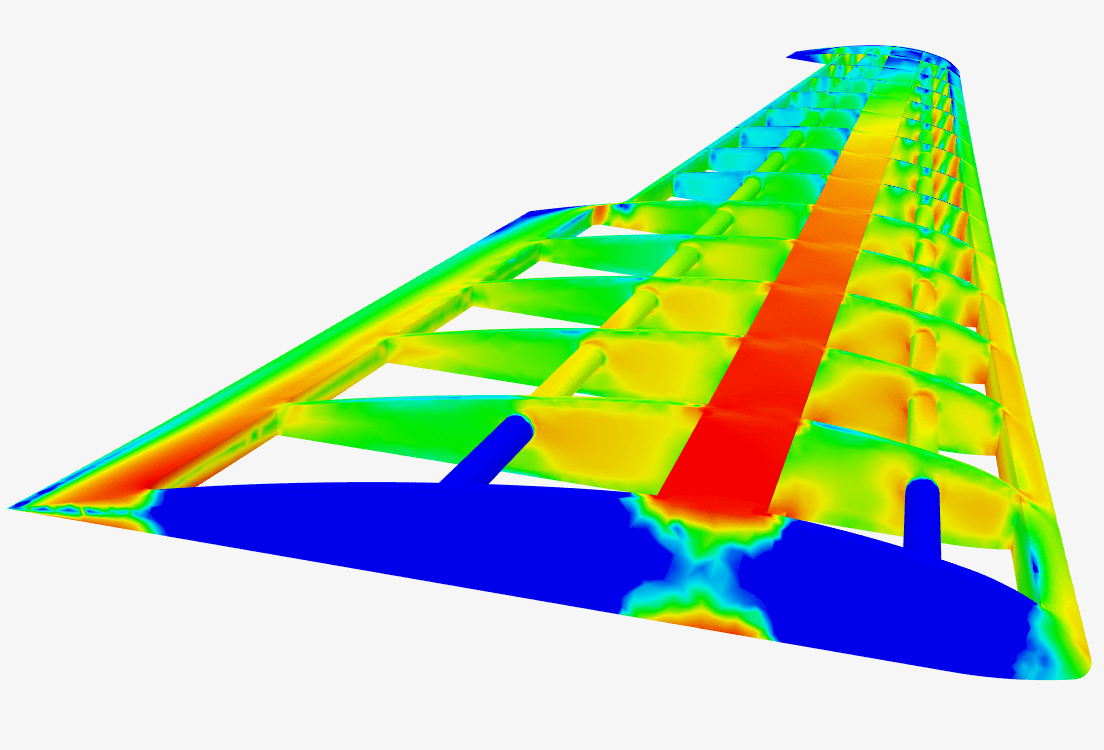

Tosca Optimization Technology – Topology and Non-parametric Optimization

The Tosca optimization suite provides dedicated fast and powerful structural and flow optimization solutions based on finite element analysis (FEA) and computational fluid dynamics (CFD) simulations.

Product development costs are often determined in the early concept phase. The automatic generation of optimized design proposals reduces your number of product development cycles and the number of physical prototypes. Product performance is increased, and the development costs are significantly reduced. Starting with the definition of the maximum allowed design space, Tosca Optimization helps you to find the design that fits the design space and considers all product requirements.

Structure Optimization delivers powerful optimization solutions for design of lightweight, stiff, and durable parts and assemblies within shorter development cycles to maximize performance, minimize material and weight, and discover new design possibilities.

Tosca Structure offers functionalities for topology, shape, bead, and sizing optimization. Existing designs often only need small changes to improve the overall product performance. Using Tosca Structure’s optimization methods, the relevant product requirements can be considered. Design improvements are realized in a shorter development time.

Fluid Optimization enables topology optimization-driven design concepts for fluid flow systems and components. Use its capabilities to create innovative designs automatically for a defined flow task and available package space. Fluid Optimization’s unique technology helps you achieve the highest flow performance, quality, and eco-efficiency.

Key benefits:

Accelerate conceptual design, reducing time-to-market

Support ready-to-manufacture product design

Save weight and ensure the highest result quality for reliable components

Avoid error-prone and time-consuming model simplification

Handle nonlinearities directly within the optimization

Define structural optimization tasks interactively

Create fluid flow devices with reduced pressure drop and improved flow uniformity

Efficiently and accurately simulating noise and vibration across the entire audible frequency range is crucial to meeting customer expectations and complying with regulations.

Next Generation Vibro-Acoustics and Aero-Vibro-Acoustics Simulation

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration is increasing due to government environmental legislation, new lightweight materials and constructions, detectability, fatigue, consumer expectations, and competitive pressures.

Characterize the complex sources acting on your systems (including complex unsteady flow sources), diagnose and rank the various transmission paths of noise through the system, and get accurate models of the frequency-dependent dissipation and isolation that arises from poroelastic noise control treatments and structural isolators.

Wave6 provides unique analysis methods for efficiently and accurately simulating noise and vibration across the entire audible frequency range. These methods are integrated into a single, common engine and controlled by a single license. This enables you to combine methods in the same model and efficiently analyze noise and vibration problems in ways that are simply not possible in other software packages. By integrating Wave6 into your design process you can ensure noise and vibration performance is built into your product at the design stage, which reduces the risk of discovering expensive problems during physical prototyping and testing.

Key benefits:

Aeroacoustics of exterior flow noise from a rigid structure

Vibro-acoustics via airborne and structure-borne transmission paths

Aero-vibro-acoustics of interior wind noise due to fluctuating surface pressures

Statistical Energy Analysis (SEA) methods for analyzing vibro-acoustic response of components at mid and high frequencies and wave propagation through arbitrary cross-sections

Structural finite elements for analyzing vibration of components at low frequencies

Acoustic Boundary Elements for simulating acoustic wave propagation in bounded or unbounded acoustic spaces at low frequencies

Acoustic finite elements for describing the response of bounded acoustic spaces at low frequencies

Linear and quadratic acoustic elements account for variations in acoustic properties due to temperature and pressure variations computed using CFD

ABAQUS(Simulia) Industries